septiembre 24, 2025

How to Optimize the Layout of an Industrial Warehouse for Greater Productivity

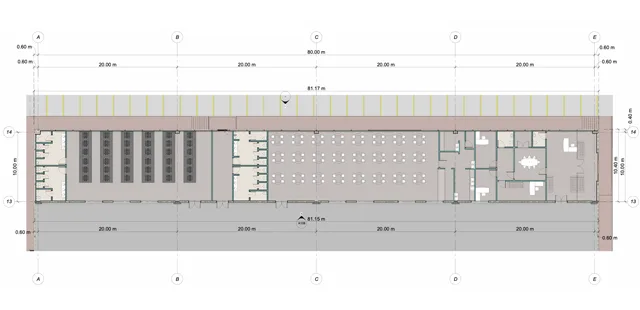

In the industrial world, the internal distribution of a warehouse is key to achieving high levels of efficiency and competitiveness. A well-designed layout not only boosts productivity but also reduces costs, streamlines processes, and ensures worker safety.

At TESSIN Constructora, we know that every square meter counts. That’s why we share the best practices to optimize your industrial warehouse layout in Mexico.

- Analyze the Workflow

The first step is to map out production processes. A design that follows the natural sequence of production avoids unnecessary movements, saves time, and improves operational efficiency.

- Maximize Space Utilization

A good layout makes the most of available height and surface. Consider vertical racks, wide aisles, and strategically placed storage areas to enhance logistics.

- Prioritize Safety

Industrial safety must be integrated into the design. Emergency exits, clear signage, and evacuation routes are essential to protect workers.

- Design for Flexibility

The market changes, and your warehouse must adapt. A flexible layout makes it easier to expand production lines, relocate machinery, and implement new technologies.

- Integrate Technology

Using simulation software and 3D design allows you to foresee errors and optimize distribution before construction, saving both time and money.

Benefits of an Optimized Layout

- Increased productivity

- Reduced logistics costs

- Greater worker safety

- Adaptability to new demands

- Full use of available space

At TESSIN Constructora, we design and build industrial warehouses in Mexico with strategic layouts that boost your business productivity.

Contact us today and take your project to the next level.